Hot akpọrepu enweghị enweghị nkebi ígwè tube ọkpọkọ

Ọkpọkpọ igwe anaghị agba nchara

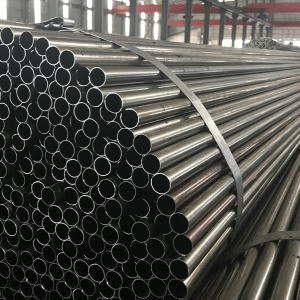

A na-emepụta tubes igwe na-ekpo ọkụ na-ekpo ọkụ na-enweghị nkebi na nkeji ọkpọkọ akpaaka.

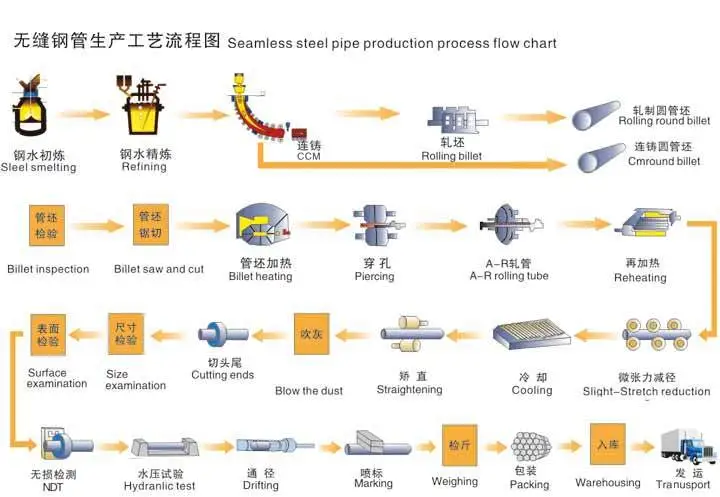

A na-enyocha oghere tube siri ike ma wepụ ntụpọ dị n'elu, bee n'ime ogologo oge achọrọ, dabere na njedebe perforated nke oghere oghere ahụ, wee ziga ya na ọkụ ọkụ ọkụ maka ikpo ọkụ na ịkpọpu na igwe ọkpọ.Ọ na-aga n'ihu na-atụgharị ma na-aga n'ihu n'oge oghere ọkpọ.N'okpuru mmetụta nke rollers na njedebe, oghere tube na-adị nwayọọ nwayọọ nwayọọ, nke a na-akpọ nnukwu ọkpọkọ.Mgbe ahụ, a na-eziga ya na igwe na-atụgharị ọkpọkọ akpaka ka ọ gaa n'ihu na-atụgharị.N'ikpeazụ, a na-eme ka ọkpụkpụ na-ekpuchi mgbidi ahụ site na igwe na-edozi ahụ, na dayameta na-ekpebi site na igwe nha iji mezuo ihe ndị a chọrọ.Iji nkeji na-akpụgharị ọkpọkọ na-aga n'ihu iji mepụta ọkpọkọ nchara na-ekpo ọkụ na-ekpo ọkụ bụ usoro dị elu karịa.

Igwe ọkụ na-ekpo ọkụ na-ekpo ọkụ na-enweghị nkebi: tube oghere → kpo oku → perforation → mpịakọta mpịakọta atọ, ntụgharị na-aga n'ihu ma ọ bụ extrusion → iwepụ tube → nha (ma ọ bụ mbelata dayameta) → jụrụ oyi → billet tube → ịgbatị → ule nrụgide hydraulic (ma ọ bụ nchọpụta ntụpọ) → akara → ụlọ nkwakọba ihe

Ụdị na Ụkpụrụ

1.Seamless ígwè ọkpọkọ maka structural ojiji (GBT8162-1999).A na-eji ya eme ihe maka nhazi izugbe na nhazi igwe.Ihe nnọchianya ya (ọkwa): carbon ígwè, Nke 20, na No. 45 ígwè;Alloy ígwè Q345, 20Cr, 40Cr, 20CrMo, 30-35CrMo, 42CrMo, wdg.

2.Seamless ígwè ọkpọkọ maka ibufe mmiri mmiri (GBT8163-1999).A na-eji ya eme ihe maka ibufe pipeline mmiri na injinia na akụrụngwa buru ibu.Ihe nnọchi anya (akara ule) bụ 20, Q345, wdg.

3.Seamless ígwè ọkpọkọ maka obere na-ajụ nrụgide boilers (GB3087-1999) na-eji rụpụta superheated uzuoku ọkpọkọ, esi mmiri ọkpọkọ maka ala na-ajụ nrụgide boilers nke dị iche iche Ọdịdị, superheated uzuoku ọkpọkọ, nnukwu anwụrụ ọkụ ọkpọkọ, obere anwụrụ anwụrụ ọkụ na arch brik maka ọkụ ọkụ locomotive.Carbon structural ígwè dị elu nke na-ekpo ọkụ na-ekpo ọkụ na oyi na-atụ (kpọre) ọkpọkọ na-enweghị ntụpọ maka ọkpọkọ.Ihe nnọchiteanya bụ Nke 10 na Nke 20 ígwè.

4.Seamless ígwè ọkpọkọ maka ikpo ọkụ ọkụ dị elu (GB5310-1995) bụ ihe dị elu nke carbon ígwè, alloy steel na igwe anaghị agba nchara na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na n'elu.Ihe nnọchi anya bụ 20G, 12Cr1MoVG, 15CrMoG, wdg.

5.Seamless ígwè ọkpọkọ maka elu-nrụgide fatịlaịza akụrụngwa (GB1479-2000) bụ elu-edu carbon structural ígwè na alloy ígwè enweghị nkebi ígwè ọkpọkọ adabara chemical ngwá na pipelines na-arụ ọrụ okpomọkụ nke -40 ~ 400 ℃ na-arụ ọrụ nrụgide nke 10 ~ 30Ma.Ihe nnọchi anya bụ 20, 16Mn, 12CrMo, 12Cr2Mo, wdg.

6.Seamless ígwè ọkpọkọ maka petroleum cracking (GB9948-1988).A na-eji ya eme ihe na igwe ọkụ, ndị na-agbanwe ọkụ na pipeline maka ibufe mmiri n'ụlọ nrụpụta mmanụ ala.Ihe nnọchi anya ya bụ 20, 12CrMo, 1Cr5Mo, 1Cr19Ni11Nb, wdg.

7.Steel ọkpọkọ maka mgbapu ala (YB235-70) bụ ọkpọkọ ígwè nke ngalaba geological na-eji maka isi ihe.Enwere ike kewaa ha n'ime ọkpọkọ ọkpọkọ, akwa ọkpọkọ, ọkpọkọ isi, casings na ọkpọkọ sedimentation dịka ojiji ha si dị.

8.Seamless ígwè ọkpọkọ maka diamond core drilling (GB3423-82) bụ igwe anaghị agba nchara nke a na-eji maka ọkpọkọ ọkpọkọ, isi mkpara na casing maka diamond isi mgbapu.

9.Oil na-egwupụta ọkpọkọ (YB528-65) bụ ọkpọkọ nchara na-enweghị ntụpọ nke na-agbapụta n'ime ma ọ bụ nke mpụga na nsọtụ abụọ a na-eji maka mkpọ mmanụ.E nwere ụdị ọkpọkọ ígwè abụọ: wired na unthreaded.A na-ejikọta ọkpọkọ eriri na nkwonkwo, ebe a na-ejikọta ọkpọkọ na-enweghị eriri na nkwonkwo ngwá ọrụ site na ịgbado ọkụ.

10.Ihe mkpuchi Carbon Steel Coilna carbon-manganese ígwè enweghị nkebi ígwè ọkpọkọ maka ụgbọ mmiri (GB5312-1999) bụ carbon ígwè enweghị nkebi ígwè ọkpọkọ eji na n'ichepụta ụgbọ mmiri 'Klas I mgbali na-eguzogide ọkpọkọ pipes, Class II mgbali na-eguzogide ọkpọkọ usoro, boilers na superheaters.Okpomọkụ na-arụ ọrụ nke mgbidi igwe anaghị agba nchara anaghị agafe 450 ° C, yana okpomọkụ na-arụ ọrụ nke mgbidi ọkpọkọ nchara na-enweghị ihe karịrị 450 ° C.Ihe nnọchianya bụ 360, 410, 460 ígwè akara ule, wdg.

11.Seamless ígwè ọkpọkọ maka ụgbọala ọkara aro casing (GB3088-82) bụ a elu-edu carbon structural ígwè na alloy structural ígwè ọkụ-akpọrepu enweghị nkebi ígwè anwụrụ eji maka n'ichepụta ụgbọala ọkara aro casings na ụgbọala axle ulo aro tubes.

12.High-pressure pipe mmanụ maka mmanụ dizel (GB3093-86) bụ igwe na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-eji na-emepụta ọkpọkọ dị elu maka usoro ntinye mmanụ dizel.

13.Stainless steel tube na-enweghị ihe ọ bụla maka iji ihe eji eme ihe (GB / T14975-1994) bụ igwe anaghị agba nchara na-ekpo ọkụ (extruded, gbasaa) na oyi kpọnwụrụ (akpọrela) ọkpọkọ nchara.

14.Stainless steel ọkpọkọ igwe anaghị agba nchara maka njem mmiri (GB / T14976-1994) na-ekpo ọkụ na-ekpo ọkụ (extruded, gbasaa) na oyi na-atụ (rolled) nke na-eji igwe anaghị agba nchara na-ebufe mmiri mmiri.

15.Seamless ígwè ọkpọkọ maka gas cylinders (GB18248-2000).A na-ejikarị eme ihe dị iche iche gas na hydraulic cylinders.Ihe nnọchi anya ya bụ 37Mn, 34Mn2V, 35CrMo, wdg.

Ọkpụkpụ nchara na-enweghị nkebi nwere ike ibibi usoro nkedo nke nchara nchara, nụchaa ọka nke nchara, ma wepụ ntụpọ dị na microstructure, si otú a na-eme ka usoro ígwè ahụ sie ike ma melite akụrụngwa ígwè.Nke a na-emeziwanyewanye na ntụgharị ntụgharị, nke mere na ígwè adịghịzi isotropic ruo n'ókè ụfọdụ;afụ, cracks na looseness guzobere n'oge wụsara nwekwara ike welded n'okpuru omume nke elu okpomọkụ na nrụgide.

Dị ka ọkpọkọ nchara na-enweghị nkebi n'etiti ọkpọkọ ígwè oghere, ọ nwere ihe ndị a:

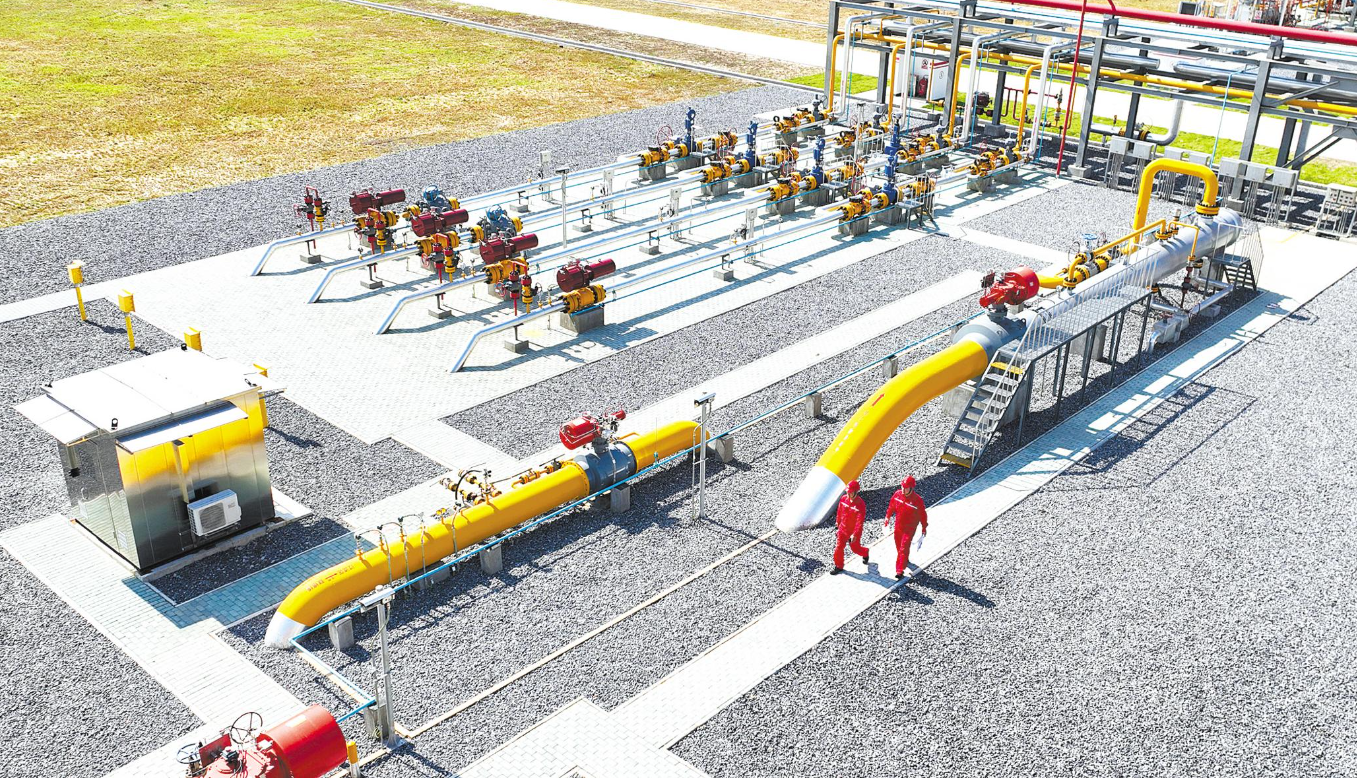

1.Oil na gas: Hot akpọrepu enweghị nkebi ígwè ọkpọkọ na-ọtụtụ ebe na-eji pipelines njem na ubi nke mmanụ, eke gas, coal gas, wdg, dị ka mmanụ olulu mmiri ọkpọkọ, mmanụ ọkpọkọ, mmanụ casings, n'okpuruala gas mmepụta pipelines, wdg.

2.Water ọkọnọ na gas: Igwe ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-adabara maka pipeline ụgbọ njem na usoro mmiri dị iche iche na gas, na-ebufe ikuku abịakọrọ, uzuoku na ubi ndị ọzọ.

Ụlọ ọrụ 3.Chemical: ọkpọkọ ígwè na-ekpo ọkụ na-ekpo ọkụ na-adaba adaba maka ngwá ọrụ kemịkalụ dị iche iche, reactors, pipeline transport, pipe clamps na ubi ndị ọzọ.

4.Shipbuilding na ụgbọ elu: A na-eji ọkpọkọ ígwè na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ n'ime ụlọ engine, usoro mgbasa ozi na akụkụ ndị ọzọ na ụgbọ mmiri, ụgbọ elu na mpaghara ndị ọzọ.

5.Other ojiji: Hot akpọrepu enweghị nkebi ígwè ọkpọkọ dịkwa mma maka mgbochi corrosion mkpuchi, ewu ubi, ígwè nrụpụta, akpaaka akụkụ, wdg.

Enwere ụdị nkwakọ ngwaahịa ọkpọkọ nchara atọ: ngwugwu, ịkụ ọkpọ, ọkpọ mmanụ ma ọ bụ ọkpọ ọkpọ mmanụ. Ọzọkwa dị ka ihe ndị ahịa chọrọ.

Ụlọ ọrụ anyị nwere nnukwu ụlọ nkwakọba ihe na China niile, na-enwe ndepụta zuru ezu na usoro nnyefe dị mkpirikpi.N'ịbụ ndị nwere ahụmahụ ọtụtụ afọ na mbupụ ihe mkpuchi, anyị nwere nkwakọ ngwaahịa ọkọlọtọ na Ụkpụrụ Ụgbọ njem maka mbupu ihe mpempe akwụkwọ, iji chebe nchekwa nke ngwongwo gị na mbupu n'ụzọ niile.Ọdabara na akpa na nnukwu ibu.

Kedu ihe kpatara ịhọrọ Lishengda Trading Co.

1. A na-asọpụrụ nkwekọrịta ma na-echekwa kredit.

2. Ọnụ ahịa asọmpi na mma dị mma.

3. ọkachamara mbupụ otu.

4.Convenient njem ebe.

5. Ogologo oge mbupu.